Professional Food Dehydrator Industrial Fruit Drying Machine

Basic Info.

| Model NO. | DY-36SH/XH(12HP) |

| Voltage | 380V |

| Customized | Customized |

| Rated Current | 21A |

| Rated Power | 11.2kw |

| Voltage/Frequency | 380V/50Hz |

| Maximum Power | 21.2kw |

| Dehumidification | 36L/H |

| Refrigerant Type | R22/R134A |

| Heating Capacity | 36kw |

| Transport Package | Seaworthy Wooden Packing |

| Specification | 1600mm*1000mm*1820mm |

| Trademark | Diye |

| Origin | Foshan, China |

| HS Code | 8419399090 |

| Production Capacity | 6000sets/Year |

Packaging & Delivery

Package Size 170.00cm * 110.00cm * 192.00cm Package Gross Weight 450.000kgProduct Description

Professional Food Dehydrator Industrial Fruit Drying MachineOperating Principle of Heat Pump DryerThe energy saving heat pump dryer machine is using inverse Carnot cycle principle and driven by a small amount of electric energy. 1) The refrigerant (Freon) is pressurized by the compressor to become a high temperature and high pressure gas (temperature up to 100ºC) before it enters the heat exchanger (condenser); 2) The refrigerant gas is condensed and liquefied in the condenser to release high temperature heat energy,which will be transferred into the drying chamber by circulating fan to heat the air there. 3) The water in the materials are vaporized through the form of hot air, and the evaporated water steam is discharged away by the dehumidification system to achieve the purpose of drying the materials in the drying chamber. 4) After condensation and heat release,the refrigerant is changed into a low temperature and low pressure liquid through the expansion valve. 5) The liquid refrigerant will continuously absorb the low heat energy of the surrounding air and quickly evaporate into a gas state when it enters the evaporator due to the sudden reduction of the pressure; 6) The refrigerant that absorbs a certain amount of energy flows back to the compressor and the next cycle begins. In this way, the refrigerant continuously circulates the heat energy in the air to the drying chamber to heat the air.

Various Drying Equipments Comparison | ||||||||||

Heating Type | Fuel Type | Energy Efficiency | Energy Consumption | Calorific Value | Unit Cost | Toal Cost | Safety Performance | Environment Effects | Labor Costs | Service Life |

Diye Air Energy Heat Pump Dryer | electricity | 300% | 37kW·h/H | 860Kcal/KG | $0.14/kW.h | $5.2/H | Safe&Reliable | None | Low | 10-15 years |

Electric heater | electricity | 95% | 107kW.h/H | 860Kcal/KG | $0.14/kW.h | $15/H | Aging electric heating tube | None | High | 5-8 years |

Oil-fired Boiler | diesel | 75% | 14KG/H | 10000Kcal/KG | $0.92/kW.h | $13/H | Oil leak/fires/explosion | Heavy Pollution | High | 6-9 years |

Coal Boiler | coal | 42% | 42KG/H | 5000Kcal/KG | $0.14/kW.h | $5.9/H | Air leak/fires | Heavy Pollution | High | 6-9 years |

Gas Boiler | gas | 75% | 14Nm³ | 10000Kcal/KG | $0.61/kW.h | $8.5/H | Gas leak/fires/explosion | Medium Pollution | High | 6-9 years |

Advantages of Cabinet Type Heat Pump Fruits Dehydrator

1) PLC and touch screen fully automatic control mode;The operation is automatically completed by a microcomputer,which can be controlled remotely.2) By using the proprietary technology of regenerative circulation heat pump dehumidification method, our dryers can save operating cost and save more than 50% energy compared with traditional drying mode.3) The integrated design of the indoor and outdoor can preheat the fresh air; It can also reduce the impact on the dyring material when the fresh air enters the drying chamber on the materials.4) Dedicated compressor and thermal expansion valve throttling technology to ensure the stability of various working conditions. 5) The dryer has a comprehensive protection function (high pressure,low pressure,exhaust,etc.) fault protection function to ensure the safe operation of the equipment.6) Drying materials are not affected by the external environment temperature,and the wide temperature range makes it easier to use in winter or in cold areas.7) It adopts closed-type condensation and dehumidification technology for drying,which can collect condensed water and dry materials with volatile components that have recycling value and dissolve in water.8) The dryers adopt cold-air dehumidification and hot-air drying methods,which is widely used for drying various fruits,vegetables,meat,seafood,nuts,leaves,agricultural products,etc.

Technical Parameters of Heat Pump Dryer

Model number | DY-18SH/XH(6HP) | DY-36SH/XH(12HP) | DY-45SH/XH(15HP) | DY-60SH/XH(20HP) | DY-75SH/XH(25HP) | DY-90SH/XH(30HP) |

Heating Capacity | 18kw | 36kw | 45kw | 60kw | 75kw | 90kw |

Dehumidification | 18L/H | 36L/H | 45L/H | 60L/H | 75L/H | 90L/H |

Refrigerant Type | R22/R134a | R22/R134a | R22/R134a | R22/R134a | R22/R134a | R22/R134a |

Rated Power | 5.6kw | 11.2kw | 13.5kw | 19.4kw | 25kw | 28.5kw |

Rated Current | 10.5A | 21A | 25.4A | 36.5A | 46.9A | 53.4A |

Maximum Power | 15.6kw | 21.2kw | 23.5kw | 39.4kw | 45kw | 48.5kw |

Maximum Current | 29A | 40A | 44A | 74A | 84.6A | 91.2A |

Voltage/Frequency | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

Protection Against Electric Shock | Class I | Class I | Class I | Class I | Class I | Class I |

Drying Chamber Temperature | 35~70ºC | 35~70ºC | 35~70ºC | 35~70ºC | 35~70ºC | 35~70ºC |

Ambient Temperature | -5~45ºC | -5~45ºC | -5~45ºC | -5~45ºC | -5~45ºC | -5~45ºC |

Maximum Exhaust Pressure | 0.7/2.8MPa | 0.7/2.8MPa | 0.7/2.8MPa | 0.7/2.8MPa | 0.7/2.8MPa | 0.7/2.8MPa |

Noise | ≤53dB | ≤53dB | ≤53dB | ≤53dB | ≤53dB | ≤53dB |

Standard Air volume | 6000m³/H | 12000m³/H | 15000m³/H | 20000m³/H | 25000m³/H | 30000m³/H |

Net Weight | 250kg | 400kg | 450kg | 520kg | 600kg | 870kg |

Dimensions(L*W*H) | 950*950*1820mm | 1600*1000*1820mm | 1600*1100*1850mm | 2000*1300*1820mm | 2000*1600*1820mm | 2000*1600*1850mm |

Fruit Drying Machine Application

Hundreds of drying projects experience; Introduced advanced manufacturing technology. Zero pollution,low energy consumption,environmental protection,energy saving heat pump dryers.Our ServicesA. Order Process INQUIRY → QUOTATION → AGREEMENT → ORDER CONFIRM → PROFORMA INOICE OR CONTRACT → DOWN PAYMENT → PRODUCTION → BALANCE PAYMENT → DELIVERY → DOCUMENTS DESPATCH → GOODS COLLECTION → INSTALLATION → OPERATION → FEEDBACK

B. OEM & ODM are welcome; C. Technical support for your installation,operation and maintenance.

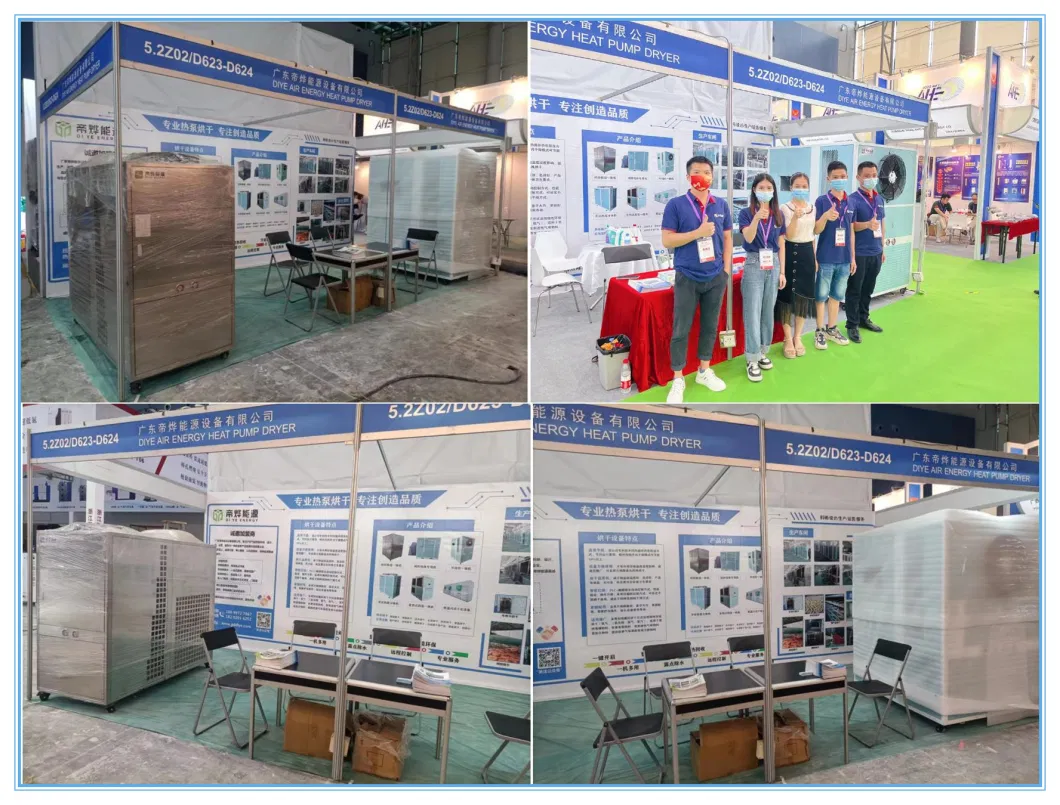

D. One year's warranty, and you can pay for extended warranty.All life time technical support. E. Spare parts and technical support at most economic prices after the warranty.Company Profile